HI-TEST is NAVSEA-approved for MIL-DTL-901 high impact shock testing.* We are the only facility that offers 24/7 testing without local restrictions. Our collection of test vehicles and expertise in the design and fabrication of custom test fixtures are available for your shock testing requirements.

Prior to testing, our team will design and fabricate the necessary test fixtures, develop test procedures, design instrumentation plans and design shock isolation systems and/or conduct shock isolation system evaluations. HI-TEST team members install your equipment, electrical power, auxiliary services and instrumentation. Our testing facility is outfitted with large capacity cranes, a machine shop, extensive instrumentation services, fully equipped observation offices and spacious conference rooms for your convenience. Following testing, HI-TEST will deliver test reports complete with plotted data, detailed test results and photos of the test set-up, along with any instances of damage and modifications.

Heavyweight Shock Testing

5 Floating Shock Platforms (FSP) for testing capacity of 100,000 + lbs

1 Intermediate Floating Shock Platform (IFSP) for testing capacity of 250,000 lbs

6 Deck Simulator Fixtures (DSF) for all deck requirements (8-10 Hz, 12-16 Hz, >25 Hz)

4 DSFs for FSPs; 2 DSFs for IFSP

A remote test site that includes 3 test basins in excess of 200 feet deep

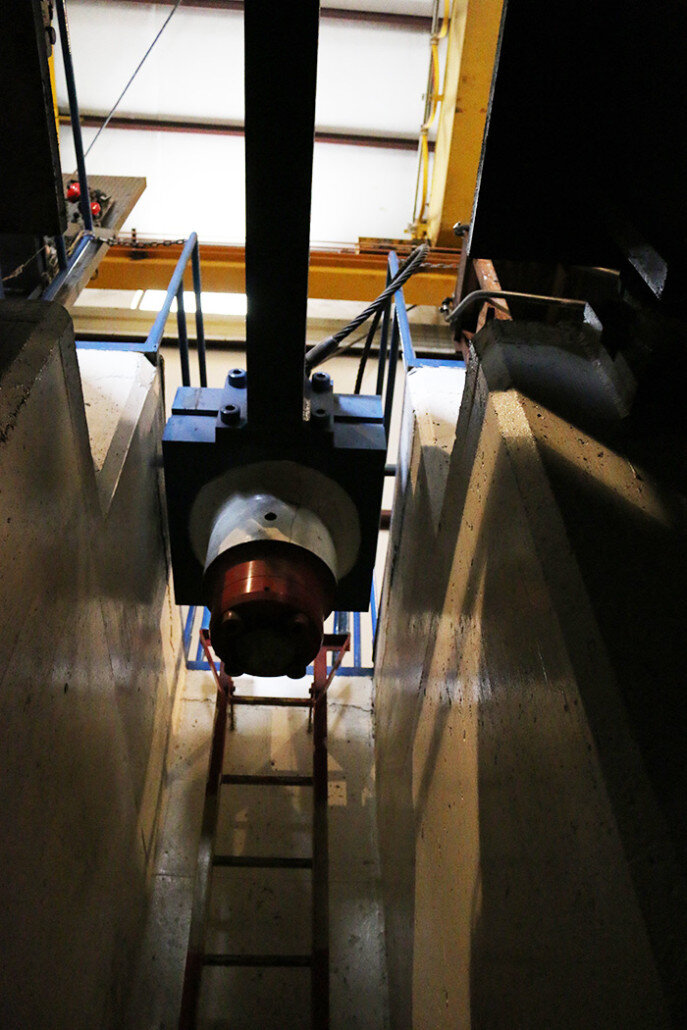

Large Displacement Shock Simulator

HI-TEST invented the Large Displacement Shock Simulator (LDSS) for use in testing COTS assemblies. The LDSS has been used to test prototypes for research and design efforts prior to heavyweight shock, and has the potential to be used where obsolescence dictates the need for extension testing.

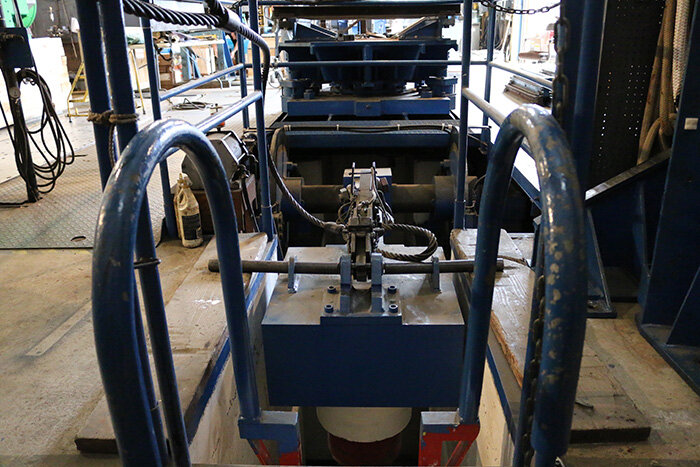

Deck Simulating Shock Machine (DSSM)

HI-TEST’s HI-TEST’s newly installed DSSM, approved for use under MIL-S-901E, is 1 of only 3 machines available world-wide. The DSSM can be used to qualify Class II components up to 2400 lbs. in lieu of heavyweight barge testing, optimizing your test program schedule and budget.

The HI-TEST DSSM is 100% company owned, incurring no costs and/or delays due to DFARS Part 45.

Lightweight & Medium Weight Shock Testing

HI-TEST has one Lightweight Shock Machine, one Medium Weight Shock Machine, and all standard test fixtures

Lightweight and Medium Weight shock testing is conducted efficiently, with assistance offered for research and development of equipment designs. Standard tests are conducted in 1-3 days.

HI-TEST also is available to fabricate, install and/or calibrate shock test machines and platforms. We have built and installed numerous lightweight and medium weight shock testing machines for both domestic and foreign customers, and have built and customized heavy weight shock testing platforms, including barges and deck simulator fixtures, for both domestic and foreign test facilities. Our experienced engineers and fabricators can manufacture any machine, platform, test fixture or other component that you may need for mechanical shock testing.

*Per NAVSEA Inst. 9491.1C, March 21, 1996.